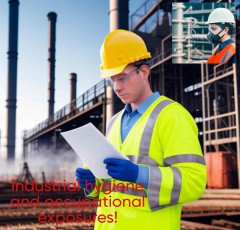

Industrial Hygiene And Occupational Exposures

Industrial hygiene is the science and practice of locating, analyzing, and reducing workplace risks that could endanger employees' health or well-being. It entails foreseeing, identifying, assessing, and controlling potential workplace dangers.

When a worker comes into touch with a physical, chemical, or biological agent at work that has the potential to be harmful, this is referred to as occupational exposure. A worker may be exposed at work by ingestion, inhalation, or skin contact with potentially harmful elements.

Occupational exposures and industrial hygiene address the possible health and safety risks connected to the workplace and work to reduce or eliminate these risks using a variety of strategies, including engineering controls, administrative controls, personal protective equipment (PPE), worker education, and training.

Chemical, physical, biological, and ergonomic risks are a few of the typical workplace hazards that industrial hygiene and occupational exposure specialists may run into.

Chemical risks include exposure to solvents, insecticides, and heavy metals, as examples. Physical risks can include vibration, radiation, and noise. Viral, bacterial, and fungal exposure are examples of biological risks. Repetitive activities, awkward postures, and heavy lifts all pose ergonomic risks.

Professionals in industrial hygiene and occupational exposure employ a number of techniques, such as air sampling, noise level monitoring, ergonomic assessments, and hazard assessments, to find and evaluate dangers in the workplace. They then create and put into place control mechanisms to lessen or completely eliminate exposure to these risks.

A safe and healthy workplace must have effective occupational exposure control and industrial hygiene initiatives.

They can increase worker productivity, lessen the expense of workers' compensation claims and lost workdays, and help to prevent diseases and injuries at the workplace.

Industrial hygiene and occupational exposure specialists are in charge of not only finding and analyzing workplace dangers, but also creating and putting into action plans to mitigate them. Implementing engineering controls, administrative controls, and personal protective equipment might all fall under this category.

Engineering controls are structural changes applied to the working environment to lessen or completely eliminate exposure to dangers. Engineering controls include things like barriers, noise-canceling insulation, and ventilation systems.

Policies and practices are put in place as administrative controls to lessen exposure to risks.

Administrative controls include things like developing safe work practices, rotating people to lessen exposure to risks, and giving instruction on how to handle tools and materials safely.

Workers wear personal protective equipment (PPE) to shield them from dangers. Respirators, gloves, safety glasses, and earplugs are a few examples of PPE.

Professionals in industrial hygiene and occupational exposure aim to reduce exposure to risks in order to prevent diseases and injuries at work. This necessitates a detailed knowledge of the risks that exist at work as well as the best practices for reducing these risks.

Investigating mishaps and accidents that happen at work may also involve experts in industrial hygiene and occupational exposure.

This may entail performing root cause analyses to ascertain what went wrong and figuring out what can be done to stop similar situations from happening in the future.

Professionals in industrial hygiene and occupational exposure may also help create emergency response plans for fires, spills of hazardous materials, and other emergencies. These plans aid in ensuring that staff members are knowledgeable about emergency procedures and equipped to deal with dangerous situations.

Professionals in occupational exposure and industrial hygiene may also be involved in regulatory compliance.

Industrial hygiene and occupational exposure specialists need to be aware of the myriad federal, state, and municipal standards that control workplace safety and health in order to make sure that their firms are compliant.

Occupational exposure and industrial hygiene are important aspects of workplace health and safety.

Industrial hygiene and occupational exposure specialists help avoid workplace injuries and illnesses, increase employee productivity, and lower expenses related to workers' compensation claims and lost workdays by finding, assessing, and controlling hazards in the workplace.

Professionals in occupational exposure and industrial hygiene also contribute significantly to the development of a culture of safety in the workplace.

They assist in educating employees about potential risks at work and offering training on safe work practices. Additionally, they collaborate with management to create policies and practices that put employee safety and health first.

An organization can gain a lot from having a good safety culture, including increased output, decreased absenteeism, and higher morale among staff members. It can also aid businesses in luring and keeping brilliant personnel who value a secure and healthy workplace.

Occupational exposure and industrial hygiene are essential elements of workplace safety and health.

Industrial hygiene and occupational exposure specialists seek to safeguard employees from accidents and illnesses while also fostering a culture of safety in the workplace by finding, assessing, and controlling workplace hazards.

The workplace safety issues like industrial hygiene and occupational exposure aren't just a concern for typical industrial settings.

Healthcare professionals might come into contact with contagious diseases, lab workers might handle dangerous chemicals or biological substances, and office workers might be exposed to ergonomic risks or poor indoor air quality.

Industrial hygiene and occupational exposure experts must also constantly adjust to new workplace dangers and conditions due to the development of new technology and changes in the nature of work. For instance, novel technologies like 3D printing or nanotechnology may create particular risks that call for novel regulatory measures.

In conclusion, occupational exposure and industrial hygiene are essential elements of workplace health and safety and safeguard employees from harm and illness. Industrial hygiene and occupational exposure specialists contribute to the creation of safe and healthy work environments for all employees through the detection, evaluation, and control of workplace risks as well as the promotion of a safety culture.

To note that those who are interested in a career in industrial hygiene and occupational exposure should think about earning a degree in occupational health and safety or a closely related field, as well as earning professional certification from bodies like the American Board of Industrial Hygiene (ABIH) or the Board of Certified Safety Professionals (BCSP).

These certifications prove that an individual has satisfied specific educational and professional experience requirements and has aced a demanding exam proving their expertise in the industry. Maintaining current with the most recent advancements and best practices in the fields of industrial hygiene and occupational exposure also requires continual education and training.

Industrial hygiene and occupational exposure are important disciplines that play a crucial role in defending employees from job dangers and fostering a workplace safety culture.

Failing to offer a safe and healthy working environment for employees is against the law and can have serious repercussions. This covers penalties, legal action, and reputational harm to a business.

In order to maintain compliance with safety standards and safeguard the health and welfare of employees, organizations may find it beneficial to have trained and qualified industrial hygiene and occupational exposure professionals on staff.

Occupational exposure and industrial hygiene are critical elements of workplace safety and health that protect employees from risks, foster a culture of safety, and guarantee adherence to safety requirements. Industrial hygiene and occupational exposure specialists use a variety of tools and techniques to efficiently identify, assess, and control workplace hazards as workplaces continue to change.

The COVID-19 epidemic has also highlighted the significance of workplace exposure and industrial hygiene.

Professionals in industrial hygiene have been in the forefront of attempts to prevent worker exposure to the virus, offering advice on tactics like social exclusion, correct PPE usage, and ventilation.

Industrial hygiene and occupational exposure specialists will continue to play a crucial role in safeguarding the safety and health of workers as workplaces continue to adjust to the current pandemic.

Occupational exposure and industrial hygiene are vital and dynamic subjects that necessitate constant learning, retraining, and adaptability to shifting workplace dangers. Organizations may assist safeguard their employees and foster a culture of safety in the workplace by emphasizing workplace safety and health and investing in competent specialists.

Additionally, occupational exposure and industrial hygiene might benefit an organization's financial line.

Organizations can cut expenditures for workers' compensation claims, medical expenses, and lost productivity by minimizing the incidence of workplace illnesses and injuries. Additionally, businesses that place a high priority on workplace safety and health may experience improvements in customer and stakeholder satisfaction, lower turnover, and staff morale.

Organizations must emphasize workplace safety and health and invest in industrial hygiene and occupational exposure specialists.

By doing this, businesses may safeguard their bottom line, foster a culture that promotes employee well-being, and provide a safe and healthy work environment for their employees.

It should be noted that occupational exposure and industrial hygiene are ethical requirements as well as issues of compliance and cost-savings. Organizations are responsible for ensuring that workers' rights to a safe and healthy working environment are upheld.

Industrial hygiene and occupational exposure specialists also have a responsibility to speak out against harmful working circumstances, promote worker safety and health, and work toward a time when all employees can do so.

Occupational exposure and industrial hygiene are crucial elements of workplace safety and health. Industrial hygiene and occupational exposure specialists seek to prevent workplace accidents and illnesses while also fostering a culture of safety through the identification, assessment, and control of potential risks. They also help to build a safe and healthy work environment. Organizations that make investments in these areas can reap rewards in terms of compliance, cost savings, greater morale, lower attrition, and improved reputation. Industrial hygiene and occupational exposure are ultimately more than just an issue of cost-effectiveness or compliance; they are also a moral requirement and a basic right of workers.

NordPass

NordPass  All Wireless Products

All Wireless Products  Artificial Intelligence

Artificial Intelligence  Best Sellers On Amazon

Best Sellers On Amazon  Amazon Best Selling Products

Amazon Best Selling Products  NordLocker

NordLocker  The Click Engine

The Click Engine  Unlimited access to classes on illustration, photography, design, film, music

Unlimited access to classes on illustration, photography, design, film, music  Online Marketing

Online Marketing  Best Home Appliances

Best Home Appliances  TitTok Revolution

TitTok Revolution  ASPINAL LONDON

ASPINAL LONDON  BEST SELLER TOP10

BEST SELLER TOP10  Graphics & Design

Graphics & Design  1150+Trendy kids coloring pages Bundle

1150+Trendy kids coloring pages Bundle  SEO Checklist

SEO Checklist  Top Rated From Amazon

Top Rated From Amazon  One World Collection

One World Collection  Best Robotic Vacuum Cleaners

Best Robotic Vacuum Cleaners  Unreal Engine 5 For Beginners Learn The Basics Of Virtual Production

Unreal Engine 5 For Beginners Learn The Basics Of Virtual Production  Smart Doorbell

Smart Doorbell  Women Fashion

Women Fashion  Online Technology Classes

Online Technology Classes  Best Selling Books

Best Selling Books  Creative Brief For Video Shoot

Creative Brief For Video Shoot  Sennheiser

Sennheiser  SOFAS

SOFAS  ELECTRONIC ACCESSORIES

ELECTRONIC ACCESSORIES  RPM 3.0

RPM 3.0  Hello Theme

Hello Theme  ASUS Laptop

ASUS Laptop  Hot Bags For Pain Relief

Hot Bags For Pain Relief  Only For The United States

Only For The United States  NordVPN

NordVPN  Men Clothing

Men Clothing  The Secret Email System

The Secret Email System  Acer Laptop

Acer Laptop  Favorite Company (Cuelinks)

Favorite Company (Cuelinks)